SAM™: Structural Steel

SAM™ offers digital management of all inspection stages of structural steel fabrication, welding & painting processes. From fabrication to document collations, SAM™ is your central source for information and reporting.

Key Benefits:

- Full monitoring: Dimensional, NDT & Coatings.

- Reports: auto-generated from one data input/import.

- Digital inspections: streamlined data recording & error reduction.

- Reporting: inspection data can be accessed at any time any where.

- Documentation Collation: Life Time Quality Record Module (LTQR).

- Revisions & Signatures: fully integrated signature and revision control system.

- Inspection Levels: By Assembly & By Weld Inspection Options.

- StruM.I.S Integration: API Written to support Live Data transfer.

0

Countries

0

Clients

0

Users

0

No. of Records

0

No. of Inspections

0

No. of Work Packs

SAM™ Core Modules

Dimensional Module

SAM™ tracks assembly dimensions, offering easy data input and fault logging. It halts faulty items, capturing photos and fixes. Issues are documented in-process and reported via a web-based NCR.

NDT Module

SAM™ streamlines weld NDT, centralizing visual, ultrasonic, and magnetic testing. It records inspections per weld, offering a single interface for all NDT tasks. Equipment, consumables, acceptance, and inspector data are captured via iOS/Android tablets.

Coatings Module

SAM™ tracks protective coating processes, documenting surface prep, application, and curing. It records environmental data, monitors thickness and adhesion, and captures images with notations for each coat. SAM™ supports multi-coat inspections for corrosion and fire protection.

LTQR Module

SAM™ automates inspection data into Lifetime Quality Records, streamlining client documentation and approval signatures. It manages revisions and numbering, ensuring secure digital archiving. Link sharing simplifies access to contract, phase, and load/lot details.

SAM™ Elcometer Integration

Bluetooth Connectivity

SAM™ connects wirelessly to Elcometer devices for seamless data transfer. No manual entry required.

Real-Time Climate Data

Environmental conditions during coating application are captured automatically. Temperature, humidity and dew point readings ensure compliance.

Dry Film Thickness Measurement

Thickness readings transfer directly to SAM™. Immediate verification against specification requirements eliminates transcription errors.

Automated Documentation

All measurements feed directly into inspection reports. Historical data remains accessible for quality assurance compliance.

SAM™ API's & Integration

Seamless Data Exchange

Custom API enables live data transfer between SAM™ and StruM.I.S. Eliminates duplicate data entry and manual reconciliation tasks.

Real-Time Information

Critical fabrication data flows between systems instantly. Field teams access up-to-date information without delay or discrepancies.

Training & Support

Integration doesn't just happen between software, we provide dedicated training for the SAM™ Steel inspection software platform & support.

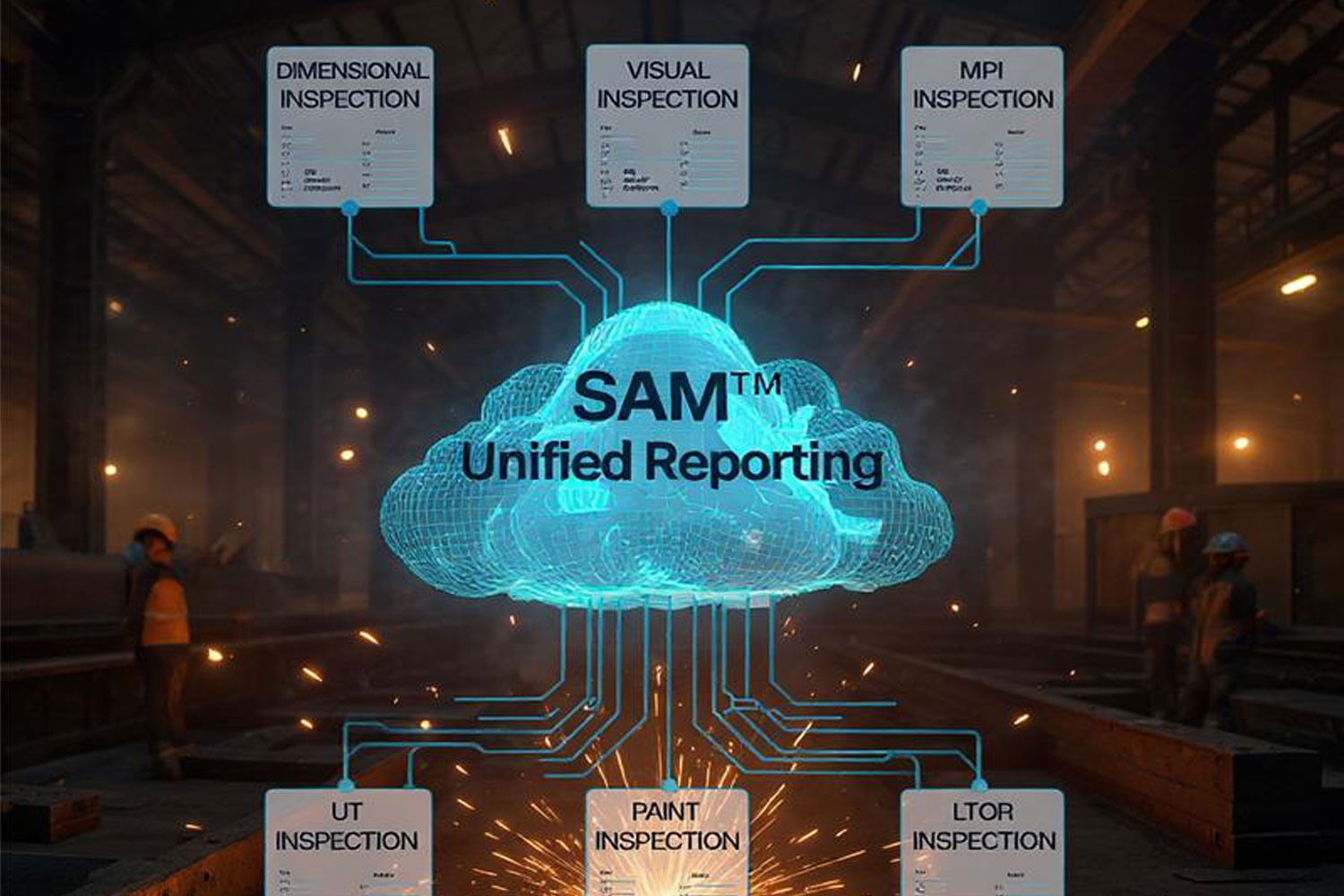

Unified Reporting

Consolidated data powers, Automated workflow ensures consistency between design and inspection phases.

Automated Data Collection

Inspection data flows directly into client documentation templates. No manual re-entry required.

Digital Approval Workflow

Secure electronic signatures streamline stakeholder sign-offs. Approval status tracked in real-time.

Revision Management

Document versioning and numbering handled automatically. Complete audit trail maintained.

Secure Digital Archiving

Lifetime records stored securely in the cloud. Available for compliance audits anytime.

Questions?

We're happy to answer any queries you may have.

Schedule a Demo

Contact us to arrange a personalised demonstration.

Contact Details

Email: info@consultsurface.com

Tel: 01224 766 651